To further expand the portfolio of activities targeted at industrialists, E-CAM has established a series of new events targeted at training interested industrial researchers on the simulation and modelling techniques implemented in specific codes and in the direct use of this software for their industrial applications.

The first event of this series will focus on the area of meso- and multiscale simulations and on the flagship code DL_MESO:

Industry Training at the MESOSCALE

22nd – 25th March 2021

Online / UKRI STFC Daresbury Laboratory

Website: https://www.cecam.org/workshop-details/1074

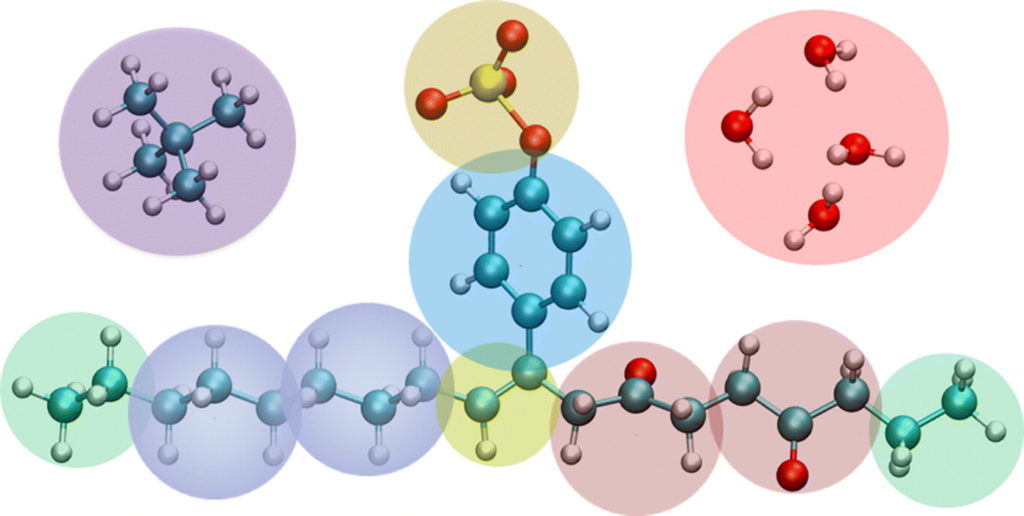

In this workshop we will introduce DL_MESO: a software package for mesoscale simulations. Usage of the software will be gradually presented, starting with tutorials based on theoretical background and following up with hands-on sessions. We will focus on the Dissipative Particle Dynamics (DPD) methodology, exploring the different capabilities of DL_MESO_DPD via practical examples that reflect daily industrial challenges.

DL_MESO has been used for a wide range of problems of both scientific and industrial interest. The code is used, for example, in projects with Unilever, Syngenta and Infineum – to develop DPD parameterisation strategies and simulation protocols to predict important properties of newly-devised surfactant-based formulations; with IBM Research Europe – to model nanofluidic multiphase. The code developers themselves will provide the training. The event is co-organized by Formeric, a company that helps industrial users to study their own formulated projects, primarily by developing a software platform to make it easier for them to access DPD simulations and modelling tools.

As part of the event, UKRI STFC offers a 6-month one seat free licence of DL_MESO 2.7 to be used soon after the end of the event, which will help testing the software.

Don’t miss this opportunity to be trained by the experts on the methods and on the codes themselves! Register for event at

www.cecam.org/workshop-details/1074/